Introduction

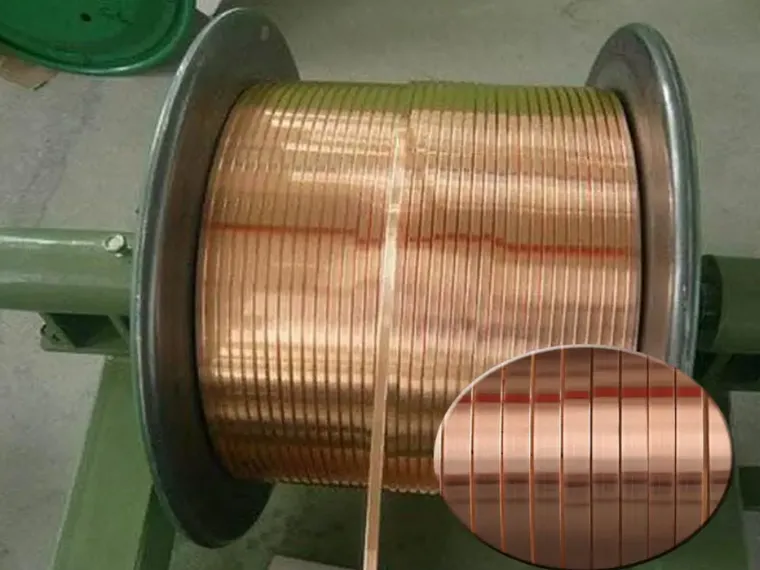

Enameled rectangular wire—also known as flat magnet wire—is an essential material in modern life, widely used across the electrical, automotive, and industrial markets. As the demand for efficient and compact electrical components continues to grow, the need for high-quality enameled rectangular wire has reached an all-time high. Whether applied in motors, transformers, or precision instruments, this type of wire delivers outstanding performance thanks to its superior conductivity, excellent heat resistance, and space-saving design. But how is it manufactured? More importantly, what equipment is required to produce enameled rectangular wire, and how can manufacturers and suppliers guarantee top quality at a competitive price?

In this blog, we will explore the key rolling and drawing equipment used in the production of enameled flat and rectangular wire. We will also examine cost considerations, highlight manufacturing in China with Sky Bluer Industries Company, and outline what buyers should look for when choosing a manufacturer or supplier.

Core Equipment for Producing Enameled Flat Wire

Producing enameled flat wire involves several steps: drawing, rolling, annealing, enameling, and quality testing. Each step requires specialized equipment that ensures accuracy and consistency.

- Wire Drawing Machines

Wire drawing machines are divided into single-die wire drawing machines and multi-die wire drawing machines. Depending on the diameter of the raw material—whether oxygen-free copper rod or oxygen copper rod—and the user’s specific requirements for the finished product, we determine which type of wire drawing machine to use. Single-die machines are typically applied for larger diameters or smaller production volumes, while multi-die machines are better suited for continuous, high-speed production of fine wires with consistent quality. This flexibility ensures that the manufacturing process can meet diverse application needs while maintaining efficiency and precision.

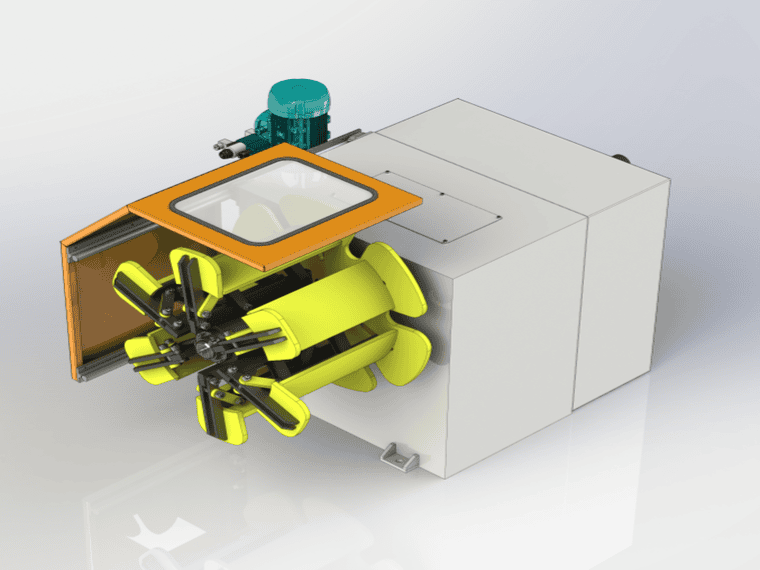

- Wire Rolling Mills

We offer a variety of rolling mills for customers to choose from, including both cold rolling mills and hot rolling mills. Depending on your requirements for the R angle of the finished product, we provide options such as two-roll mills and four-roll mills to achieve the desired precision and surface quality. Furthermore, we can configure the roll gap adjustment method based on your specific needs—whether through advanced servo adjustment for high accuracy and automation, or manual adjustment for greater simplicity and flexibility. This tailored approach ensures that every customer can find the most suitable solution for their production process.

Buyers evaluating price and cost should note that advanced rolling mills can reduce material waste and improve efficiency, offsetting higher initial investments.

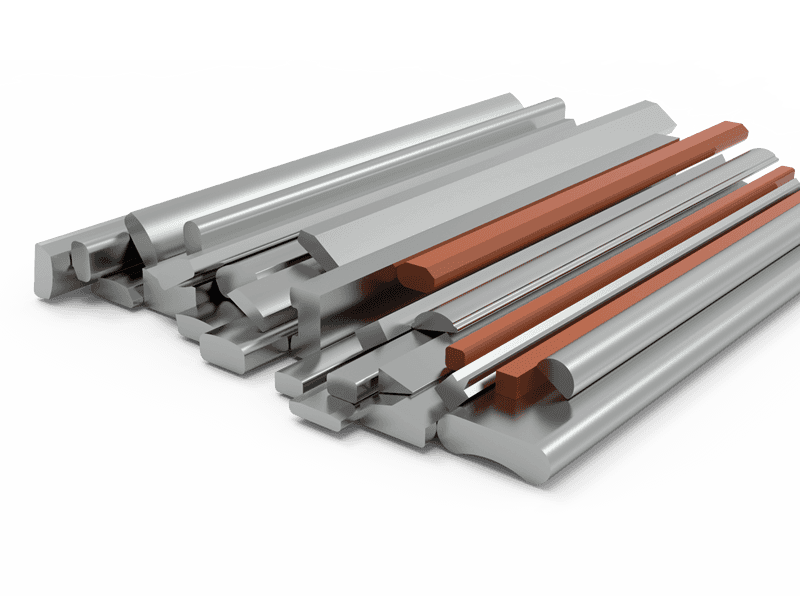

Raw Materials for Producing High-Quality Enameled Flat Wire

The typical input size for producing enameled flat wire depends on the raw material and desired finished dimensions. Standard applications usually start with copper or aluminum rods 6–20 mm in diameter, while ultra-fine or specialized wire may use rods as small as 3 mm.

To produce high-performance enameled flat wire, the choice of raw materials is crucial. The primary materials include copper or aluminum rods and premium insulating enamel coatings. For applications demanding superior conductivity and durability, oxygen-free copper (OFC) is the preferred option, while electrolytic tough pitch copper (ETP) offers a cost-effective solution for standard electrical uses. Aluminum rods provide a lightweight, economical alternative, ideal for automotive and transformer applications. The insulating enamel—ranging from polyurethane for easy soldering, polyester for general use, polyester-imide for enhanced thermal resistance, to polyimide for extreme environments—ensures the wire’s reliability and longevity. Complementary materials such as high-quality lubricants, cleaning agents, and spools support smooth processing and precise handling, allowing manufacturers to deliver the best performance at an optimal price.

Wire flattening mills can be classified into two main types: single stand mills and tandem mills. Single stand mills consist of one pair of rollers, while tandem mills comprise several roller sets arranged in a row. Tandem mills offer higher efficiency and better quality control as the wire passes through multiple roller sets; this ensures consistent and precise flattening.

Some important factors influencing the output quality of a wire flattening mill include:

- Roller material: The durability and precision of the flattening process depend on the quality of the rollers. High-quality tungsten carbide rollers feature excellent wear resistance and ensure a longer service life for the mill.

- Wire tension control: Inconsistent tension during the wire flattening process can lead to shape variations or surface defects. A proper tension control system is essential for achieving uniform and smooth output quality.

- Lubrication: Adequate lubrication between the rollers and wire is crucial to minimize friction and prevent surface damage. Efficient lubrication systems ensure smooth operation and prolong the life of the rollers.

Wire flattening mills play an essential role in manufacturing by transforming round wires into various cross-section shapes for diverse applications. Single stand and tandem mills offer distinct advantages and cater to different processing needs. Careful consideration of factors such as roller material, tension control, and lubrication ensures the optimal performance of these machines.

Typical Size for Enameled Flat Wire

Enameled flat wire comes in a range of widths and thicknesses depending on its application:

- Standard Applications:

- Width: 0.1 mm – 3 mm

- Thickness: 0.05 mm – 1 mm

- High-Precision or Specialized Applications:

- Width: 0.05 mm – 0.1 mm

- Thickness: 0.02 mm – 0.05 mm

The size is chosen based on the electrical, thermal, and space requirements of the device, such as motors, transformers, or precision instruments.

Differences Between Enameled Flat Wire Machines Produced by European and Chinese Manufacturers

French Company:

The five-stand precision rolling mill developed by a French manufacturer features an alternating arrangement of three flat rolling stands for flattening and two edge rolling stands for shaping the sides and R corners. This alternating process transforms incoming round wire into high-quality flat wire with smooth edges and precise R corners.

The complete line includes: Pay-off → Wire Straightener → Flat Rolling Stand (1) → Edge Rolling Stand (2) → Flat Rolling Stand (3) → Edge Rolling Stand (4) → Flat Rolling Stand (5) → Air Dryer → Polishing Machine → Online Dimension Measuring System → Take-up Machine.

With this advanced configuration, the mill achieves production speeds of up to 200 meters per minute, ensuring both efficiency and accuracy in flat wire manufacturing

Sky Bluer Company

Sky Bluer Environmental Technology Co., Ltd., a leading Chinese manufacturer, developed a five-stand precision rolling mill with a five-stage continuous rolling and combined drawing structure. The system actively transforms input round bars into high-quality rectangular wire with smooth edges and precisely shaped R corners.

The production line integrates: Pay-off → Wire Straightener → Flat Rolling Stand (1) → Edge Rolling Stand (2) → Flat Rolling Stand (3) → Edge Rolling Stand (4) → Flat Rolling Stand (5) → Drawing Machine (6) → Air Dryer → Polishing Machine → Online Dimension Measuring System → Take-up Machine.

With this advanced configuration, the mill delivers production speeds of up to 680 meters per minute, ensuring efficiency and precision in every stage of flat wire manufacturing.

Conclusion

Choosing between European and Chinese enameled flat wire machines ultimately comes down to your production goals, budget, and technical requirements. European manufacturers deliver high-precision equipment with advanced technology and strong after-sales support, making them ideal for specialized, high-quality applications. Chinese manufacturers, on the other hand, offer cost-effective solutions with faster delivery times, well-suited for standard production needs.

By carefully weighing factors such as customization options, overall cost, technical support, and production scale, you can identify the machine that best fits your manufacturing strategy.

If you’d like expert guidance in selecting the right enameled flat wire machine or need detailed technical specifications, we’re here to help.