Introduction

In mid-October25 2025, we were honored to welcome our valued Vietnamese customer to visit our factory and discuss cooperation on stainless steel wedge wire equipment. The visit aimed to enhance technical communication, explore future collaboration opportunities, and strengthen our long-term business partnership.

About the Vietnamese Customers

Our customer from Ho Chi Minh City, Vietnam, is engaged in the food filtration and screening industry. This visit marked his first time purchasing equipment from China, representing a meaningful milestone in building mutual trust and promoting technical exchange between our two companies.

The food filtration industry demands exceptional standards of hygiene, corrosion resistance, and precision—qualities that make stainless steel wedge wire an ideal choice. Manufactured from food-grade stainless steel such as 304, 321, or 316L, wedge wire screens offer excellent durability and easy maintenance, effectively preventing contamination during the filtration process. Their uniform slot openings and smooth surfaces ensure efficient liquid–solid separation without clogging, while their robust construction withstands high temperatures and pressure.

Moreover, wedge wire filters can be backwashed and reused, significantly reducing maintenance costs. They are widely used in sugar syrup, beer, juice, dairy processing, and water treatment systems, making them one of the most reliable and efficient solutions for modern food processing. Our Vietnamese customer is a recognized leader in these industries, and this cooperation marks the beginning of a promising partnership.

Factory Tour and Technical Demonstration

During the visit, our guests were given a comprehensive tour of the wedge wire equipment and screen mesh production line, covering all key processes including precision wire rolling, drawing, welding, polishing, and forming. They were particularly impressed by our automated production technology and our high-speed, strict quality control system.

Our technical team provided a detailed demonstration, highlighting how the equipment ensures uniform slot openings, monitors induction rates at each pass, and tracks wire shape changes throughout the rolling stages. They also explained how the process achieves smooth surface finishing and maintains consistent mechanical performance—all essential factors for producing high-quality wedge wire screens for food filtration.

The visitors expressed their appreciation for the professionalism, technical expertise, and innovative approach demonstrated throughout the production process.

Technical Discussion and Project Cooperation

Following the factory tour, we held a detailed meeting with our Vietnamese customer to discuss wedge and V shaped wire project requirements. The conversation covered wedge screen welding machine specifications, production capacity, customization options, and local service support in Vietnam.

Our engineers also demonstrated the capabilities of the latest wedge wire welding and cutting machines…

Through constructive discussion, both sides reached a preliminary agreement on cooperation and planned the next steps for equipment testing and project evaluation.

Stainless Steel Wedge Wire Sample Testing

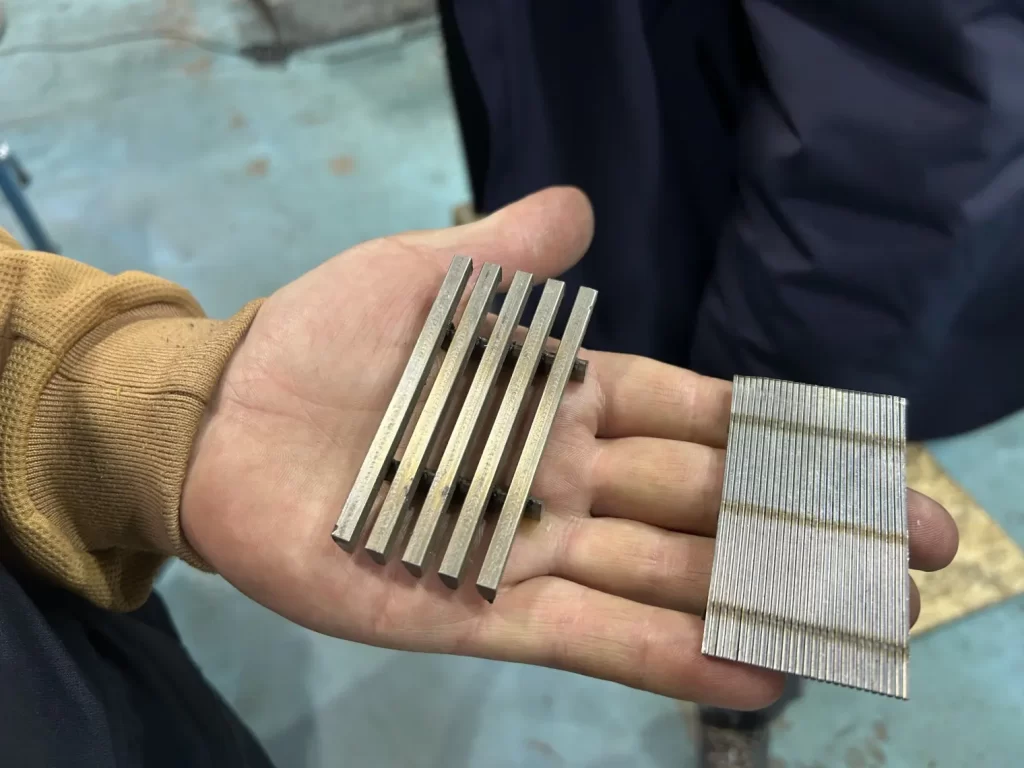

As part of our commitment to quality, we conducted a comprehensive series of tests on the stainless steel wedge wire screens for our Vietnamese customer. These tests included dimensional accuracy checks to ensure uniform slot openings, surface finish inspections to verify smoothness, mechanical strength testing to measure durability, corrosion resistance evaluations suitable for food filtration applications, and flow rate and filtration efficiency tests to confirm optimal liquid–solid separation. Prior to the customer’s visit, we had already prepared stainless steel round wire as raw material for the trial machine. During the visit, the Vietnamese customer also brought additional raw materials for on-site testing. They observed each step of the process and witnessed firsthand how our equipment consistently produces high-quality, precise, and durable wedge wire screens, reinforcing confidence in their performance for food filtration applications. The customer expressed great satisfaction with the test results and the reliability of our production process.

Conclusion

The visit allowed our Vietnamese customers and our team to actively exchange knowledge and explore new collaboration opportunities. It showcased Sky Bluer’s technical expertise and production capabilities while highlighting our commitment to delivering advanced wedge wire equipment solutions to global partners. We sincerely thank our Vietnamese colleagues for their trust and cooperation, and we look forward to achieving new successes together in the near future.

User FAQ

Answering all Your Need with Wedge Wire Screen Machines

Common Questions in Stainless Steel Wedge Wire Production — and How to Solve Them

Slot opening accuracy is one of the most critical factors in wedge wire screen quality. Even a small deviation can affect filtration precision and flow rate.

To maintain consistency:

- Use high-precision clamping jigs and a stable feeding system.

- Regularly calibrate the welding electrode and servo system.

- Control welding parameters such as current, voltage, and wire tension.

Automated wedge wire welding machines with closed-loop control can significantly improve accuracy and product consistency.

Deformation often occurs due to uneven heating, excessive welding current, or improper cooling during production.

To prevent this problem:

- Optimize heat distribution and cooling systems.

- Ensure that the base rod and wedge wire are properly aligned and supported.

- Use balanced clamping pressure to minimize thermal stress.

Maintaining a uniform temperature throughout the welding process helps ensure that each screen remains straight and dimensionally stable.

Wire breakage and weak joints are common challenges in wedge wire manufacturing. These issues often arise from unstable feeding, oxidized wire surfaces, or incorrect welding settings.

Solutions include:

- Cleaning the wire and base rods before welding to remove oil or oxidation.

- Adjusting current and electrode pressure to achieve a stable arc.

- Using high-purity protective gas to improve weld strength and surface quality.

Regular inspection of wire feeding rollers and machine components can also prevent mechanical stress that leads to breakage.

We introduced the operation of the CRM2025 wedge wire machine to our Vietnamese customer and explained that the machine is not only compatible with the stainless steel grades 304, 321, and 316L that he typically uses, but also supports a wide range of additional materials, including…

304 Stainless Steel – The most commonly used grade for general applications. It offers good corrosion resistance and mechanical strength, suitable for non-corrosive environments such as freshwater and basic filtration systems.

304L Stainless Steel – A low-carbon version of 304 that minimizes carbide precipitation during welding, making it better for applications requiring frequent welding and cleaning.

316L Stainless Steel – Excellent corrosion resistance, especially against chlorides and acids. Ideal for food processing, chemical filtration, seawater treatment, and pharmaceutical applications.

321 Stainless Steel – Titanium-stabilized stainless steel with superior resistance to high-temperature oxidation and intergranular corrosion. Commonly used in thermal processing and high-temperature filtration systems.

310S Stainless Steel – High-chromium, high-nickel alloy providing excellent oxidation and heat resistance. Suitable for very high-temperature filtration or drying applications.

2205 Duplex Stainless Steel – Offers double the strength of standard austenitic grades and excellent resistance to stress corrosion cracking and pitting. Recommended for harsh seawater or chemical filtration environments.

904L Stainless Steel – Super austenitic grade with very high resistance to acids, chlorides, and seawater corrosion. Ideal for marine and chemical industries where extreme corrosion resistance is required.

Titanium (Grade 2) – Lightweight and exceptionally corrosion-resistant, especially in chloride and saltwater media. Common in desalination, medical, and high-purity filtration applications.

Hastelloy or Inconel Alloys – Nickel-based alloys used in highly corrosive chemical and petrochemical environments, providing outstanding resistance to acids and oxidation.

After welding, some wedge wire screens may show oxidation or discoloration. To achieve a bright, clean surface:

- Use argon gas protection during welding to reduce oxidation.

- Perform acid pickling or electro-polishing after fabrication.

- Apply mechanical polishing for additional smoothness and aesthetic appearance.

These finishing processes not only enhance appearance but also improve corrosion resistance and product hygiene—especially important in food and beverage filtration applications.

Efficiency and precision can coexist with the right process design and equipment.

- Adopt automatic wedge wire welding machines with digital control systems.

- Implement online laser measurement to monitor slot accuracy in real time.

- Schedule regular maintenance and calibration to minimize downtime.

- Provide operator training to ensure proper handling and troubleshooting.

Through automation and process optimization, manufacturers can achieve higher output and more stable product quality.