Wedge Wire Screen Welding Machine CRM-W2026

The CRM-W2026 is a precision screen welding machine for stainless steel wedge wire screens, featuring CNC control and stable performance. It ensures high accuracy, flexible slot adjustment, and perfect circularity.

- Screen Diameter: 300–800 mm

- Screen Tube Length: Max. 4000 mm

- Gap Setting: 0.075–10 mm

- Welding Speed: 0–25 rpm

- Feeding Speed: Max. 80 mm/min

- Accuracy: ±0.015 mm

- Control: Servo CNC lifting & loadcell pressure control

- Power: Medium-frequency DC welding, 800A

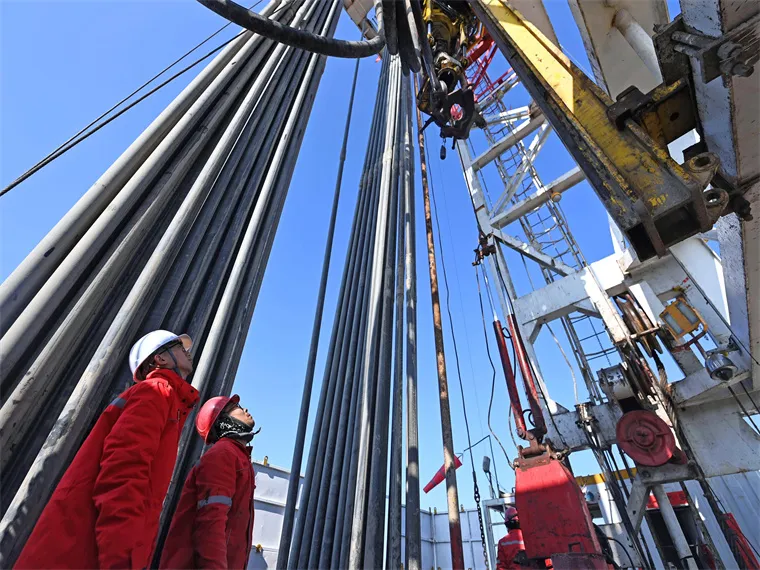

Widely used in water treatment, mining, petrochemical, and filtration industries.

Which sizes are compatible with our Wedge Mesh Screen Production Lines?

Wedge Wire Product Specifications

Thickness (mm) | Tolerance (mm) | Width (mm) | Tolerance (mm) | Area (mm²) | Hardness | Tensile (Mpa) | Others | Material |

1.78 | ±0.75 | 12.7 | ±0.10 | 21.619 | / | 850–1200 | /Q235 | 304, 316l |

2.00 | ±0.10 | 10 | ±0.10 | 19.966 | / | 850–1200 | / | 400 |

2.50 | ±0.03 | 4 | ±0.05 | 9.923 | HV300–500 | / | / | 304L |

2.66 | ±0.03 | 10 | ±0.05 | 26.091 | / | 650–750 | ≥276N/mm² | |

3.00 | ±0.03 | 8 | ±0.05 | 23.785 | HV300–500 | / | / | |

3.00 | ±0.10 | 12.7 | ±0.10 | 37.888 | / | 750–900 | / | |

3.00 | ±0.10 | 32 | ±0.10 | 95.966 | / | 900–1200 | / | |

2.00 | ±0.02 | 3.0 | ±0.02 | 4.487 | / | / | / | |

2.286 | ±0.01 | 3.56 | ±0.076 | 5.988 | HRC28–33 | 900–1030 | ≥15% | |

10.0 | ±0.05 | 3.4 | ±0.03 | 32.027 | HRC37–39 | / | / | |

2.00 | ±0.05 | 5.0 | ±0.05 | 8.664 | / | 1150–1350 | / | |

2.00 | ±0.05 | 12 | ±0.05 | 22.664 | / | 1100–1400 | / | |

4.60 | ±0.10 | 15 | ±0.20 | 63.608 | HV300–450 | / | ≥276N/mm² | |

10.0 | ±0.05 | 3.4 | ±0.03 | 32.027 | HRC37–39 | / | / | |

5.00 | ±0.05 | 44 | ±0.05 | 252.282 | / | / | / | |

5.00 | ±0.05 | 38 | ±0.10 | 211.221 | HV250–350 | / | / | |

4.00 | ±0.03 | 11 | ±0.05 | 20.151 | / | 800–1150 | / |

Equipment for Producing Wedge Wire Screens

Established in 2006, Sky Bluer China specializes in manufacturing equipment for stainless steel wedge wire and Wedge Wire Screens. With years of expertise, we provide complete production solutions to meet the needs of filtration, separation, and screening industries.

Our main production lines include:

- Stainless Steel V-Wire Drawing Machines – for precision wire forming and stable quality output.

- Stainless Steel Wedge Wire Rolling & Drawing Machines – ensuring accurate wire profiles for high-performance screens.

- Wedge Wire Screen Welding Machines – advanced welding systems for reliable and durable screen assembly.

- The CRM800-4100 Wedge Wire Screen Welding Machine combines precision, efficiency, and durability to meet the demanding requirements of wedge wire screen production. With advanced CNC control, flexible slot adjustment, and reliable welding accuracy, it ensures consistent product quality and high productivity. This makes it an ideal choice for manufacturers in water treatment, mining, petrochemical, and filtration industries seeking long-term performance and efficiency.

Wedge wire filter elements provide precise filtration, durability, high strength, corrosion resistance, and efficient flow capacity for industrial, water treatment, and separation applications.

Stainless steel Internals support grid ensures stability, strength, uniform load distribution, corrosion resistance, and long-term reliability in reactors, separators, and industrial filtration systems.

Wedge wire filter nozzles deliver precise filtration, prevent media loss, ensure uniform flow distribution, resist corrosion, and provide durability in water treatment and industrial filtration systems.

Technical Information on Wedge Mesh Screen Production Lines

- Materials: Stainless steels (304, 316L, 321, 310S), Duplex steels (2205, 2507), Hastelloy, Titanium alloys, and other specialized metals.

- Surface Wire Profile: Triangular (V-shaped / wedge) wires for optimal filtration performance.

- Support Wire Profile: Options include triangular (V-shaped / wedge), round rods, flat bars, water-drop, and square wires.

- Slot Size Range: 0.02 mm – 10 mm, adjustable to meet precise separation requirements.

- Pitch: 10 mm – 100 mm.

- Surface Wire Length: Up to 3,000 mm.

- Support Wire Length: Up to 4,000 mm.

Frequently Asked Questioins

Our Wedge Wire Screen Welding Machine production line Designed for high-precision filtration, separation, and industrial screening applications, these wedge mesh screens combine durable materials with customizable geometries to meet a wide range of process requirements

The CRM800-4100 can produce screen tubes with diameters from 300 mm to 800 mm and lengths up to 4000 mm.

The machine achieves ±0.015 mm welding accuracy, with adjustable slot gaps ranging from 0.075 mm to 10 mm.

Yes, it can process standard wedge wire profiles and can also be customized for special profiles if required. This includes, but is not limited to, wedge wire screen tubes, wedge wire screen panels, wedge wire filter elements, wedge wire screen cylinders, centrifugal baskets, rotary drum screens, wedge wire filter nozzles, lateral assemblies, internal support grids, water well screens, mining screens, sand screens, food and beverage screens, Sieve Bend screens, and more.

Welding speed ranges from 0–25 rpm, with a feeding speed up to 300 mm/min, ensuring both efficiency and flexibility depending on screen specifications.

The machine uses a loadcell-based pressure control system, which ensures consistent welding force for reliable screen quality.

Regular maintenance includes checking the copper welding wheel, electrodes, and lubrication system. Spare parts such as copper wheels, electrodes, and sensors are recommended for uninterrupted production.