High-Precision Rectangular Copper Wire Production Line - CRM2025-96C

The CRM2025-96C rectangular copper wire production line is a high-precision rolling equipment developed and manufactured by our factory. It is designed to produce premium-quality rectangular copper wires widely used in applications such as transformers, traction motors, CTC conductors, alternators, high-voltage motors, and generators. As a leading manufacturer in China, we specialize in providing advanced winding wire machines to meet the diverse needs of the industry.

Details of Rectangular Copper Wire Production Line

- Payoff Machines

- Wire Takeup Machines

- Rolling Mills

Payoff Machines in Rectangular Copper Wire Production Machinery

Various types of wire payoff machines are used in rectangular copper winding wire production lines, including static and dynamic models. A popular option is the CRM2025 Horizontal Reel Payoff, along with vertical coil payoffs. These machines are designed to handle loading weights ranging from 5 kg to 200 kg, providing versatility and efficiency for different production requirements.

Wire Takeup Machines in Rectangular Copper Wire Production Machinery

Our Sky Bluer team offers a wide range of wire takeup machines to meet diverse production requirements. These include:

• Standard Takeup Machines

• Heavy-Duty Spool/Coil Takeups

• Trunk-Type Wire Takeup Machines

• Inverted Wire Takeup Machines

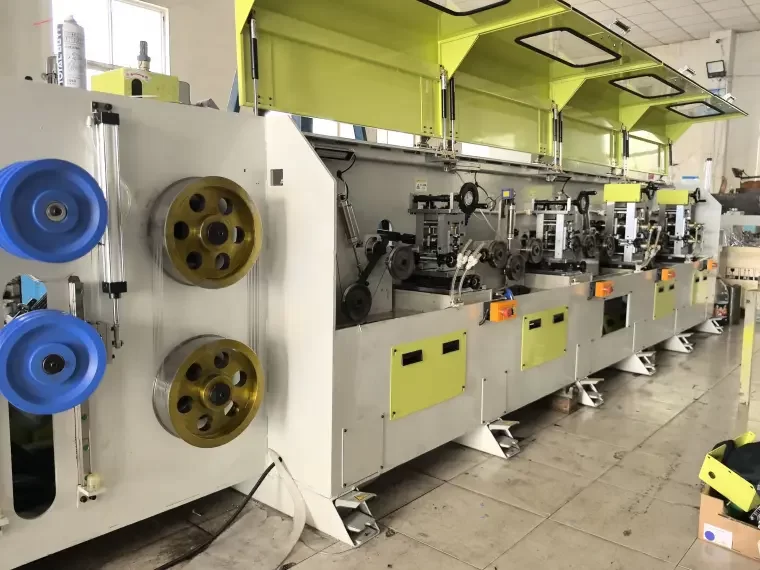

Rolling Mills in Enamelled Rectangular Copper Wire Production Machinery

In the production of copper flat wire or rectangular wire, the choice of rolling mill depends on the R-angle requirements of the finished product. We offer two classic models to meet diverse production needs:

1. 2-Hi Rolling Mill: This model is ideal for producing natural arc flat wires or rectangular wires with a simple and efficient design.

2. Turks Head Mill (4-Hi Rolling Mill): Featuring four rolls, this advanced mill provides superior control over the width of the finished product, ensuring precise and consistent dimensions.

Both models are designed for high performance and reliability, making them essential components in enamelled rectangular copper wire production lines.

Overview of Rectangular Copper Wire

Rectangular copper wire is a high-purity conductor with a rectangular cross-section, produced by rolling or drawing round copper wire. Designed for higher space factor, improved thermal performance, and lower electrical resistance, it is ideal for coils, transformers, motors, and generators. Often enamelled or insulated for magnet wire applications, it is widely used in high-efficiency motors, electric vehicles, and other equipment requiring compact, high-performance windings.

Rectangular Magnet Wire Rolling Mill

The Rectangular Magnet Wire Rolling Mill is a type of multi-stand machine designed for producing flat or rectangular wires, typically starting from round wire as the raw material.

With over 15 years of expertise, Sky Bluer China has established itself as a market leader in this field, delivering reliable and high-performance solutions for rectangular magnet wire production.

Frequently Asked Questioins

Every customer has unique needs, standards to meet, and projects with specific requirements. At Sky Bluer Industries China, we are dedicated to being your trusted partner in delivering the right solution the first time.

The production of rectangular copper wire involves a series of precision steps to ensure high-quality output. The typical process includes:

Wire Drawing/Payoff→Inline Annealing →Rolling→Polishing→Wire Take-Up

A rectangular winding wire machine, also referred to as an enameled copper flat wire machine, is designed to produce high-precision rectangular wires for various applications. The standard size range includes a thickness of 0.90 mm to 5.00 mm and a width of 2.00 mm to 16.00 mm. The recommended thickness-to-width ratio is 1.5. Our equipment is fully compatible with standard sizes commonly used in the market, ensuring reliable performance and high-quality output.

The standard bobbin diameter ranges from 200 mm to 600 mm, with coil weights varying from 20 kg to 150 kg. If you have specific requirements, we also offer customization to meet your needs.

We provide both standard takeup systems and customized solutions tailored to your specific needs, ensuring optimal performance and flexibility for rectangular copper wire production.

Complete Line

A standard line designed for medium-sized rectangular copper wire, this system efficiently covers the typical CTC wire size range—and beyond.

Design Speed: Up to 1,000 m/min

Size Range:

Minimum height: 1.00 mm

Maximum height: 5.00 mm

Minimum width: 2.50 mm

Maximum width: 15.00 mm

Yes. Edge rounding and enamel insulation can be applied depending on the application, such as reducing corona discharge or enhancing coil winding performance.

Rectangular copper wire is widely used in transformer windings (CTC), electrical motors, inductors, power generators, and other high-efficiency electrical devices.