These machines are specifically designed to produce high-quality photovoltaic ribbons, including round, flat (BC), triangular, and bus ribbons. These ribbons serve as key conductive elements in solar panels, ensuring efficient electrical connection between cells. The equipment ensures precise shaping, stable performance, and high production efficiency, making it ideal for large-scale solar manufacturing.

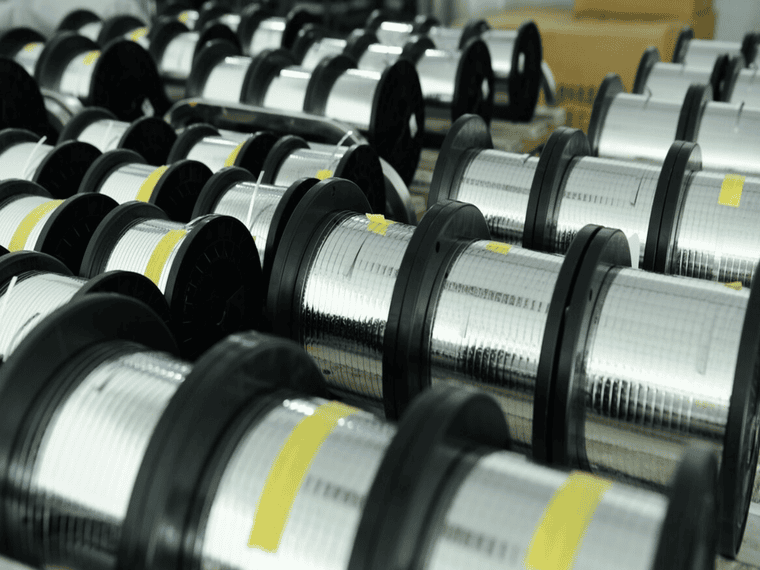

Our machines are compatible with a wide range of materials such as copper, tinned copper, and silver-coated wires. Optional features like automatic spool change, tension control, and in-line quality inspection can be configured based on your production needs.

The best designed and most suitable copper wire tinning machine with CRM Team

Experienced and dedicated professionals committed to high-quality solutions

Reliable and safe operations ensuring protection for both operators and equipment

Used in the manufacturing of photovoltaic (PV) solar panels within a module. Sky Bluer is a leading PV ribbon machine manufacturer based in China.

Precision production line designed for manufacturing 0.26mm multi-busbar (MBB) PV ribbons, ideal for high-efficiency solar cell connections.

Precision production line designed for manufacturing 0.32mm multi-busbar (MBB) PV ribbons, ideal for high-efficiency solar cell connections.

Common sizes include 0.1 mm × 0.25 mm, 0.12 mm × 0.3 mm, and 0.2 mm × 0.5 mm, but custom dimensions can also be produced…

Bus ribbons for solar panels typically range from 0.20 to 0.35 mm in thickness and 2 to 5 mm in width, commonly made of tinned or silver-coated copper,

Specialized production lines designed to manufacture triangular-shaped photovoltaic ribbons, enhanced solderability for solar cell connections.

Our continuous success in leading production lines is rooted in delivering the highest quality standards in the solar market. For decades, the world’s top solar module manufacturers based in China have relied on our PV Ribbon machines. The consistent quality of our products has helped them enhance their own products and significantly reduce production costs.

Cell- Interconnect Ribbon

Round ribbon 0.26mm, Baro copper:0.23 ± 0.004mm

Coating thickness:15 ± 5 microns

Final dimension after coating :0.26mm

Copper purity:>99.97% / Elongation: >=20%

Sky Bluer manufactures the String Interconnect Ribbon Machine, a specialized industrial equipment for the solar panel production process. It automatically solders interconnect ribbons between solar cells to form complete cell strings. The machine typically operates at a speed of approximately 400 meters per minute.

What are the typical sizes of String Interconnect Ribbon?

String Interconnect Ribbon

6*0.40mm, bare copper:0.35 ± 0.005mm

Coating thickness:25 ± 5 microns

Final Dimension after coating 6*0.40mm

Copper purity:>99.97% /Elongation: >=20%

What are the Specifications of the Standard Tabbing Ribbon?

Our machine is capable of producing the Standard Tabbing Wire, with specifications as outlined below:

Base Material: Copper (Cu)

Copper Core Dimensions:

Width: 0.500 ± 0.050 mm

Thickness: 0.200 ± 0.005 mm

Coating Quality: Hot dip tinned

Coating Alloy: Sn60Pb40 (according to EN ISO 9453)

Coating Thickness: 15 - 25 microns

Mechanical Properties:

Tensile Strength (Rm): max. 270 MPa

Yield Strength (Rp0.2): max. 90 MPa

Elongation (A): min. 25%

Spool: HKV 160

Standard Tabbing Wire Specification

Base Material: Copper (Cu)

Copper Core Diameter: 0.320 ± 0.100 mm

Coating Quality: Hot dip tinned

Coating Alloy: Sn60Pb40 (according to EN ISO 9453)

Coating Thickness: 10 - 20 microns

Mechanical Properties:

Yield Strength (Rp0.2): max. 90 MPa

Elongation (A): min. 25%

Spool: 10SB

Standard Bus Ribbon Specification

Base Material: Copper (Cu)

Copper Core Dimensions:

Width: 5.000 ± 0.080 mm

Thickness: 0.300 ± 0.010 mm

Coating Quality: Hot dip tinned

Coating Alloy: Sn60Pb40 (according to EN ISO 9453)

Coating Thickness: 15 - 25 microns

Mechanical Properties:

Tensile Strength (Rm): max. 270 MPa

Yield Strength (Rp0.2): max. 140 MPa

Elongation (A): min. 15%

Spool: 10SB

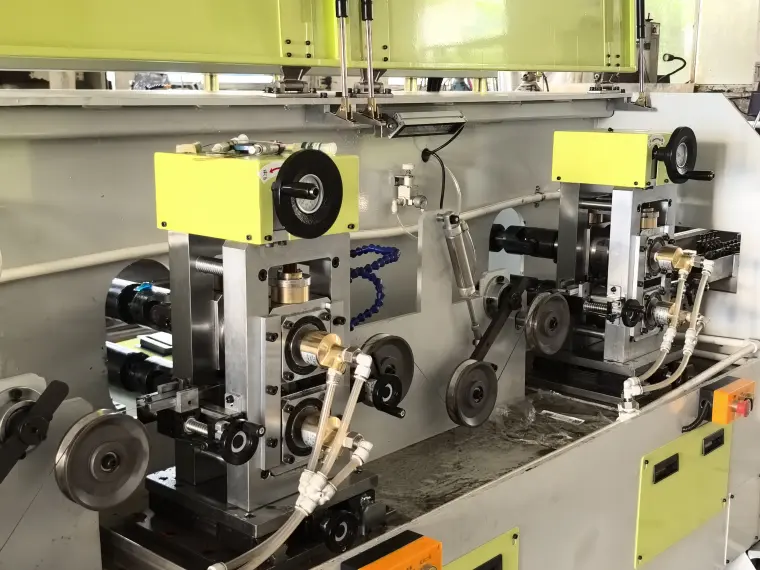

1. Operating Principle: The machine transforms round copper wire into photovoltaic ribbons through a sequence of processes, including annealing, cleaning, hot-tin coating, cooling, and precision winding.

2. Quality Characteristics:

o Consistent coating thickness

o Smooth, glossy surface

o No tin beads (slag) or pinholes

o Ensures stable product quality throughout production

3. User-Friendly Control System:

o Equipped with a man-machine interface for intuitive operation

o Features a built-in round wire mode to simplify setup and adjustments

4. Mechanical Properties:

o Yield strength of ≥56 MPa, ensuring robust and reliable performance

The CRM Research Team and Applications Engineers work together to develop customized products and processes that deliver cost-effective solutions to solar module manufacturers worldwide.

Tabbing ribbon, also known as PV ribbon or bus ribbon, plays a crucial role in connecting solar cells within a photovoltaic module. While often used interchangeably, the main distinction lies in size and function: bus ribbon is typically wider and sometimes thicker than tabbing ribbon.

You can think of tabbing ribbon as the "roads" that carry current across individual solar cells, while bus ribbon acts as the "highways" that collect and transmit current from multiple cells. Because it handles more electrical current, bus ribbon has a larger cross-sectional area. For reference, bus ribbon typically ranges from 5 mm to 6 mm in width, though certain applications may require even wider ribbons—sometimes more than twice that size.

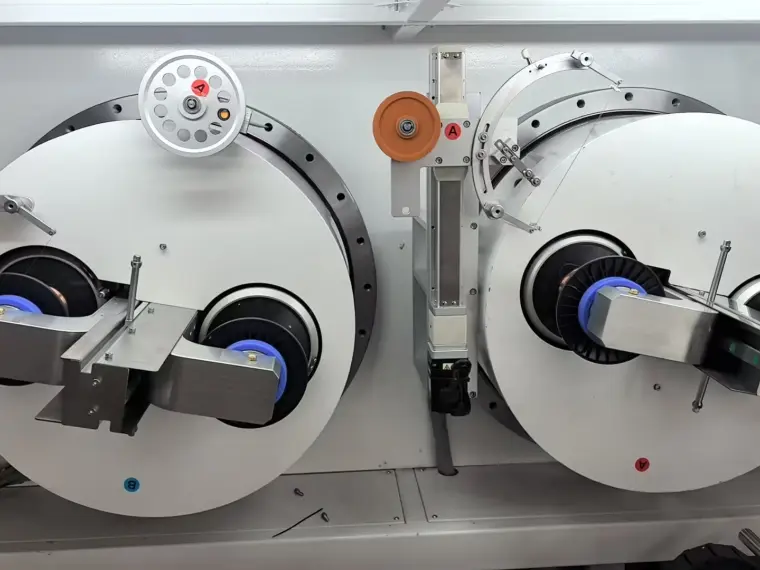

At SKY BLUER CHINA, we have engineered the CRM909 machine model specifically for the efficient production of solar tabbing ribbon. This advanced production line includes the following key processes:

1. Copper Rod Drawing

2. Induction Annealing

3. Precision Rolling

4. Tin Coating via Electroplating

5. Winding and Spooling

This integrated system ensures consistent quality, high conductivity, and optimal solderability—critical for modern photovoltaic applications.

Our PV ribbon and Busbar machine adopts an induction annealing method, with independently driven upper and lower annealing wheels. The PLC controls the motor speed by sending direct signals, while a swing rod adjusts the speed differential between the motors. Compared to traditional systems that rely on potentiometer-based motor control, this setup results in reduced swing rod movement, making it especially suitable for small-diameter ribbon production. This design ensures that the annealed copper wire is not subjected to tension from swing rod adjustments during the annealing process, thereby enhancing wire quality and consistency.

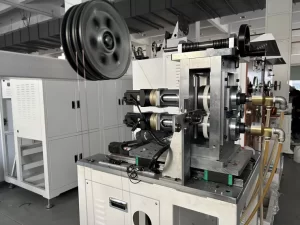

Wire Drawing Machine in PV Ribbon Production

In most solar panel production lines, a wire drawing machine is typically required alongside the PV ribbon machine. Since PV ribbons are made from thin, tinned copper wire, the drawing machine pulls the copper wire through a series of dies to achieve the desired thickness and surface finish before it is fed into the PV ribbon machine. Our most common model is the 24D wire drawing machine, which processes input size Φ1.2mm and outputs wire sizes ranging from 0.1mm to 0.4mm.