PV Ribbon Machines

The PV Ribbon Machine, officially known as the Photovoltaic Ribbon Tin Coating Machine, is an advanced piece of equipment primarily utilized for the production of high-quality solar photovoltaic copper ribbons. This sophisticated machine is capable of applying a range of coatings, including various lead-containing and lead-free solders, as well as tin, tin-lead, and tin-lead-silver alloys.

components

What Makes Up a Copper Wire Tinning Line?

Below, we will provide a complete introduction to the key components of this production line, allowing you to not only understand our equipment but also gain insight into the transformation process from oxygen-free copper wire to tinned wire.

24D Dual Wire Drawing Machines

This copper wire drawing machine processes wires with an input diameter of 0.5–1.2 mm and reduces them to an output diameter of 0.10–0.40 mm.

Dual Induction Annealing System

Employs an induction annealing featuring independently driven upper and lower annealing wheels, controlled by a PLC system for precise temperature and speed regulation.

Tin-Alloy Hot Coating Machines

A miniaturized tin furnace (120 kg/line) reduces tin accumulation at the furnace bottom, minimizing power consumption and preventing alloy stratification

Flux

Remove oxides and impurities from the surface of the metal (usually copper or aluminum) to ensure strong, clean solder joints

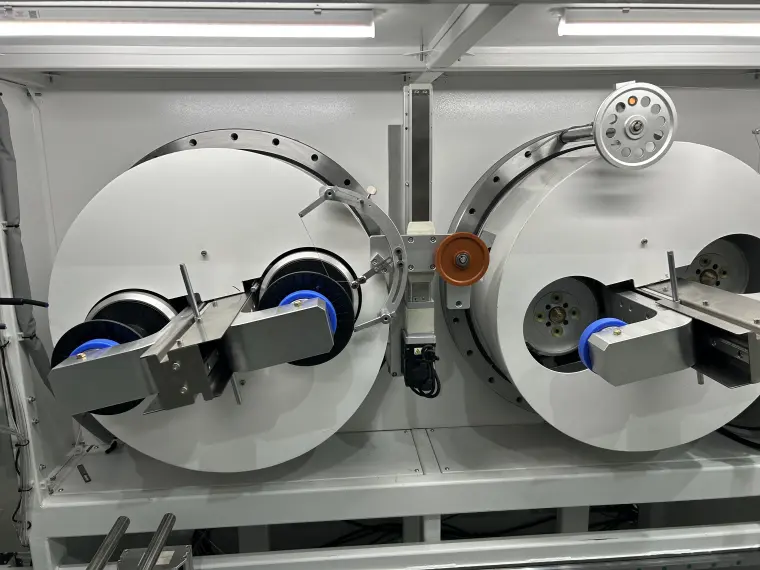

Dual Takeups

Spools are automatically switched between the left and right shafts.While the A-axis works, the B-axis remains on standby at the starting winding point…

Dual Rolling Machines

As a backup rolling mill, we have reserved all the necessary interfaces for manufacturing BC flat wire for your future market expansion.

MBB PV Ribbon Machines

Size range:φ0.23 mm-φ0.43 mm

MBB are thin, rounded copper wires that do not require ribbons across the solar cell, rather they carry current from the fingers through to interconnecting ribbons outside the front surface of the cell.

Our PV ribbon machines are used to manufacturing multi-grid modules, such as 9BB, 12BB, 15BB PV ribbons, and others. Shaded cells will be reduced, series resistance will be reduced, current density distribution will be more uniform, module power will be significantly increased by 5 to 8W, and front silver will be reduced by 30%..

What are PV ribbons and busbars

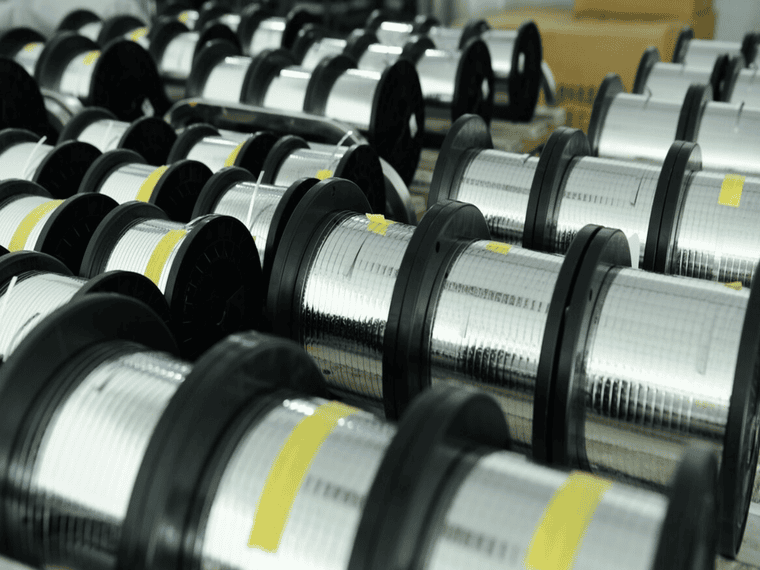

A PV tin-coated copper ribbon, commonly known as photovoltaic welding ribbon, is a type of connection material used to conduct electrical current and connect a photovoltaic module's cells.Interconnect/Tabbing Ribbon Interconnect ribbon is a hot dip tinned copper conductor installed in photovoltaic/solar panels. This PV ribbon product has a relatively wide range of uses.The interconnect ribbon is soldered directly onto silicon crystal to interconnect solar cells in a solar panel. The interconnect ribbon carries the current generated in solar cells to the PV bus bar.It offers precise control over coating thickness, ranging from 10 to 60 micrometers. The PV Ribbon machine exhibits a yield strength of ≤60-80 N/mm² (post-annealing) and a tensile strength between 190 and 250 N/mm², with elongation levels maintained below 25%. This ensures the durability and reliability of the ribbons produced, making it an essential component in solar technology manufacturing.

PV Bus Bar and PV busbar is a hot dip tinned copper conductor installed in solar panels. PV bus bar carries electric current from interconnect ribbons to the junction box. PV Busbar is also a strip material used for current transmission. It is usually made of metal materials with high electrical conductivity, such as copper or aluminum, and is very well conductive electrically. Power systems or high-power equipment usually use busbars to concentrate current between different branch lines or loads. Ensures the normal operation of a power system by carrying large currents and effectively disseminating current.

Conventional Interconnection PV Ribbon Machine

Applied to conventional 4BB, 5BB modules. Suitable for automatic stringing machines, the interconnection ribbon is welded on the main grid of the cell to connect solar cells, collect and transmit solar cell current.The PV Ribbon Continuous Rolling and Tinning Machine helps you produce the highest quality copper wire.

- Ribbon Thickness:0.15-0.3mm Ribbon Width:0.5-2.0mm

- Round ribbon wire:1.6-4.0mm

Playlist

0:16

0:16

Frequently Asked Questioins

Need a high-quality solar PV ribbon and Busbar production line? We offer one-stop solutions to maximize your factory’s efficiency. Contact us today!

- 0.20 ± 0.010

- 0.26 ± 0.010

- 0.27 ± 0.010

- 0.29 ± 0.010

When purchasing flux, you should consider its composition and performance indicators. Generally speaking, flux has three main components: activators, solvents, and surfactants. There are three main components of the flux: the activator, which promotes welding; the solvent, which dissolves and dilutes the activator and other components; and the surfactant, which enhances the wettability and fluidity of the solder.

Furthermore, when purchasing flux, you should also take into consideration its performance indicators, including viscosity, density, solid content, and pH. Viscosity refers to the fluidity of the flux, density refers to its mass per unit volume, solid content refers to the active ingredients in the flux, and pH refers to its acid-base properties.

Our technicians will also provide the most appropriate formula for the user's product, since new customers often don't know how to choose the best flux for their product.

Induction annealing is an advanced heat treatment process that offers numerous benefits for modern manufacturing. Unlike traditional methods, our photovoltaic ribbon production line is equipped with state-of-the-art induction annealing technology, providing a safer alternative to circuit-based annealing methods by significantly reducing the risk of electric shock.

Turnkey PV Ribbon Production Solutions from a Trusted China Manufacturer

As a manufacturer of PV ribbon equipment, Sky Bluer Industries in China boasts many years of experience for turnkey solutions. In this sector, our company leads the field with its tin-coated copper ribbon equipment, primarily designed to connect photovoltaic solar cells and serve as a conductive component. Our equipment has been purchased by various countries, including Canada, Japan, Turkey, Malaysia, Vietnam, South Korea, India, Brazil, and the Philippines.