- Introduction

Brief explanation of wire rolling machines and their role in wire manufacturing.

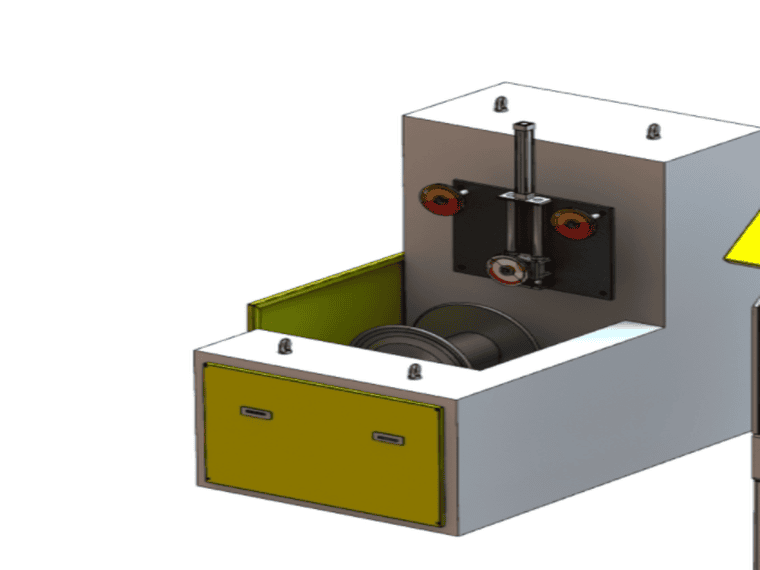

Our company specializes in small wire rolling mills, which are essential industrial machines used to shape, reduce the diameter, and enhance the chemical and physical properties of metal wire through a rolling process. These rolling mills play a critical role in wire manufacturing, transforming raw wire into a finished product with precise dimensions, superior surface finishes, and optimized mechanical properties. - In the wire production process, a rolling machine feeds the wire through a series of rollers, gradually reducing its thickness or altering its shape—such as converting round wire to flat wire. Additionally, these machines enhance the wire’s strength and surface quality, making it ideal for a wide range of applications, including cables, wires, and structural components.

- Wire rolling machines are crucial for ensuring consistency, precision, and efficiency in large-scale wire production. Their ability to process a variety of materials, such as copper, aluminum, and steel, while maintaining tight tolerances, makes them indispensable in industries like electronics, telecommunications, automotive, and construction.

- Importance of selecting the right payoff system to ensure smooth operation and high-quality output.

- Overview of the article: Discussing different types of payoffs and their advantages in wire rolling applications

Definition of a payoff in the context of wire rolling.

- In wire rolling, a payoff is the system used to feed wire into the rolling machine. It provides a steady, controlled supply of wire to be processed through the rolling mills.

- The wire is typically wound onto a spool or coil, which is then unwound by the payoff mechanism at a consistent rate. This ensures smooth operation while maintaining proper tension to prevent slack or over-tightening. Proper tension helps achieve precise wire shaping, reduces the risk of damage, and improves production efficiency.

- Payoff systems vary in design, including single-spool, dual-spool, and automatic tension-controlled models, depending on the needs of the rolling process.

Factors to Consider When Choosing a Payoff for Wire Rolling Machines

- Production Volume: The scale of production and its impact on payoff selection.

- Wire Material: Different materials (e.g., copper, steel, aluminum) may require specific payoff configurations.

o Wire Size and Type: Influence of wire diameter and shape (round, flat, etc.) on payoff choice. - Tension Control Needs: Importance of maintaining consistent wire tension for quality and precision.

- Space and Layout Constraints: How available floor space impacts the choice of payoff type.