Specializing in Alloy Wire Drawing Machines and Rolling Mills for Diverse Wire Shapes

Located in China, our factory is a leading manufacturer of alloy wire production lines. We specialize in alloy wire drawing machines and alloy wire rolling mills. Among the products of our equipment are alloy round wires, thin flat wires, square wires, and special-shaped wires.

What Is Alloy Wire?

It is made of alloy metal materials, and it has a very high plasticity. Among the most common alloy wires are aluminum alloy wires, aluminum-magnesium alloy wires, stainless steel alloy wires, steel alloy wires, DC01 alloy wires, and nickel-chrome alloy wires. Industrial, construction, decorative, handicraft, and communication equipment are among the industries that use alloy wires due to their different performance advantages.

Classification of Alloy wires

A variety of alloy wires are composed of various metals, including aluminum, potassium, iron, DC01,silver,cobalt, nickel, copper, gallium, silver, tin, gold, mercury, lead, bismuth, zirconium, and rare earth alloys. Alloys can be classified according to whether iron is present or absent.

- Ferrous alloys: The main component is iron. Some examples of ferrous alloys are stainless steel, cobalt, gallium, silver, gold, bismuth, and zirconium.

- Non-ferrous alloys: Do not contain iron as a main component. For example, aluminum, brass, bronze, copper, tin, nickel, magnesium, and titanium are some common non-ferrous alloys.

Nickel Alloy Wire Production Line

Versatile Production Line for Custom Wire Solutions

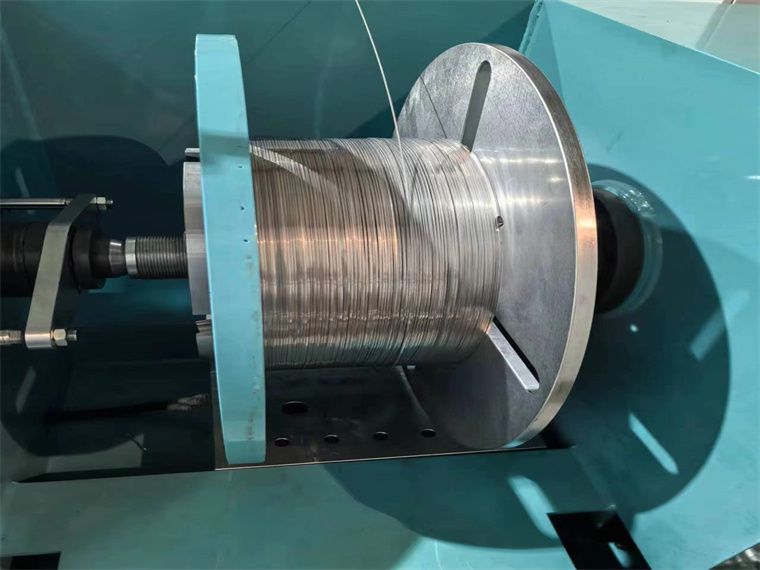

Our Nickel Alloy Wire Drawing Machine Range and Shapes

Our production line ranges from 0.020mm to 22mm for the input size, and our equipment can create wires of different shapes, including fine round wire, flat wires, strips, square wires, half round wires, and special shapes.

We offer a range of Exotic Nickel Alloys for industries of all types, with lead times as low as 60 days, we are the supplier of choice for many manufacturers.

What is alloy wire made of?

It is known that alloy steels contain chromium, nickel, manganese, molybdenum, silicon, tungsten, vanadium, and boron as the main alloying elements. Different alloy wires have different properties due to differences in these components, including hardness, toughness, corrosion resistance, magnetizability and ductility.

How much does it cost to invest in a production line for alloy wires?

A variety of factors can determine the price of alloy wire production line, including the precision requirements, the performance of the finished product, the output, the input wire range,the type of winding, the types of payoff machine as well as the supporting equipment. Your situation will determine whether you need a polishing machine, a steel brush machine, or an annealing machine.

What Is The Alloy Wire Production Line Made Up Of?

In order to produce alloy round wire, you need the following machines: precision pay-off, wire straightener, wire drawing machine, tensioner, and take-up machine

In order to produce alloy flat wires or strips, the complete alloy wire production line includes: pay-off, straightening machine, tension control, steel brush machine, high precision wire flattening machine, tension control dancers, take-up.

If you want to produce alloy special-shaped wire, we will customize the solution according to your final product requirements. The complete production line consists of: a pay-off machine, straightening machine, tension control, steel brush machine, flat wire rolling mill, four-roll universal rolling mill, tension, and take-up machine.

How fast is the Alloy Wire Production Line?

Depending on the structure of your equipment, you will get different production line speeds. For example, our wire drawing machine can reach 2000 meters per minute if you want to make aluminum wire with a diameter between 0.60 and 2.0 mm.

Contact us so we can better understand you

Every customer has unique needs, specific standards, and distinct project requirements. At Sky Bluer Industries China, we are committed to being your partner in identifying the right solution from the very start.

Feel free to reach out in whichever way works best for you—whether through live chat with an expert, filling out one of our forms, or contacting us by phone or email. We’re here to help!

Video Gallery of Different Types of Alloy Wire Production Lines

Playlist

0:16

0:16

0:16

-300x225.webp 300w, https://drawing-machines.com/wp-content/uploads/2026/02/Precision-Rolling-Mill-for-Superconducting-Flat-Copper-Wire-Production(3).webp 760w)