Metal Industry Machines With High Performance

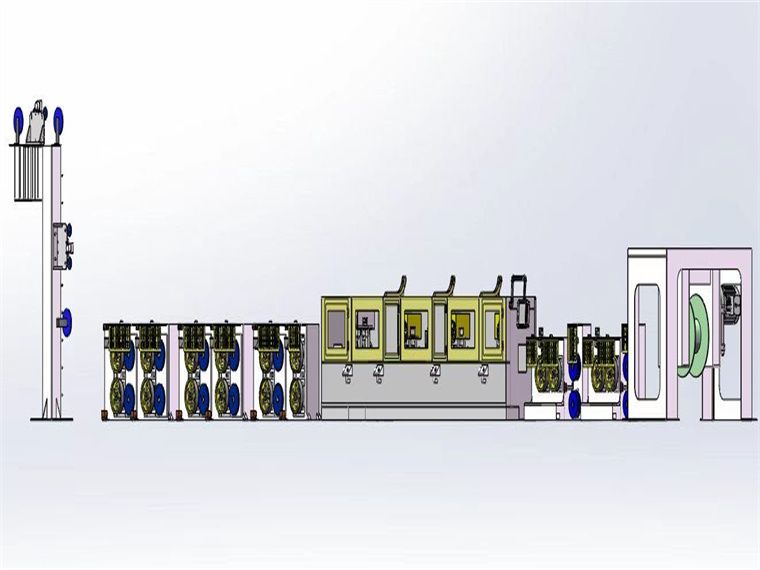

Sky Bluer Industries China manufactures high precision cold rolling mills, wire drawing machines, engineering and technical support for wire and narrow strip manufacturers. As a manufacturer and designer, we provide a range of solutions for a wide range of industries. Whether you’re looking for round wire, flat wire, square wire, or shaped wire, we provide a complete one-stop solution

Which Precision Rolling Mills Do We Offer?

The precision rolling mill is primarily used in the industrial field to make metal wires. Our precision rolling mills are primarily fed by round bars, which are rolled and shaped into the desired shape and precision following a series of rolling processes.

Round Wire Rolling Mill

round wire rolling mill is a specialized precision rolling mill designed to produce round wire by reducing the diameter of wire rods or wire stock through a series of rollers or a series of cold rolling cassette. This process involves applying pressure to deform the metal, shaping it into a round cross-section. The resulting wire is ideal for a wide range of applications, including electrical wiring, cables, fasteners, and springs.

Wire Flattening Mill

A Wire Flattening Mill, also known as a precision flat wire rolling mill, is equipment designed for producing flat and rectangular wires. The input material is typically round wire, which is then processed into a flat wire with a natural arc in its shape. This series of precision rolling mills has a broad range of applications, particularly in industries such as stainless steel, titanium, copper, brass, carbon steel, and the broader steel industry.

Advantages And Features Of Ultra-Precision Rolling Systems

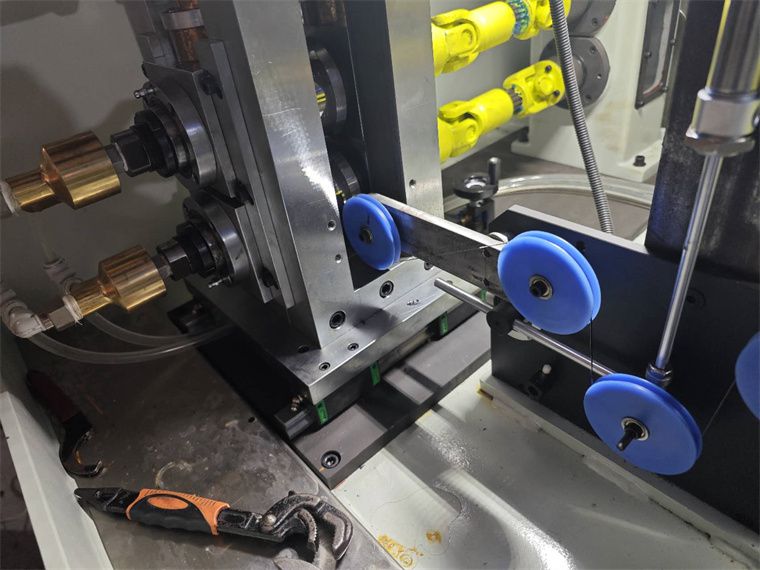

• High-precision rolling cassettes with bearing cooling

• High-precision roller adjustment – servomotor

• High Speeds

• Highly customized models

Comprehensive Solutions for Precision Cold Rolling Mills and Wire Drawing Machines

Common models

Choosing the Right Precision Rolling Mill Model

Selecting the appropriate rolling mill model is crucial for optimizing production efficiency, ensuring product quality, and reducing operating costs. Here are the key considerations to help guide your decision:

1. Material Type: Different precision rolling mills are designed for specific material grades. It’s important to consider the type of metal you’re working with—whether it’s steel (such as stainless steel, carbon steel, or iron), aluminum, or copper—as well as the material’s thickness, hardness, and the required tensile strength of the finished product. By understanding these characteristics of the raw material, we can ensure that the precision rolling mill you select is fully compatible with your material specifications, helping you achieve optimal results.

2. Production Capacity: Evaluate your required production volume. For instance, if you need to produce 1-2 tons per hour or achieve a speed of 100 meters per minute, we will select a precision rolling mill that meets these output requirements while ensuring stable performance. In doing so, we will consider factors such as production speed, product specifications, production cycles, and maintenance downtime to optimize efficiency and minimize disruptions.

3. Roller Design: The design of the precision rolling mill and the number of rolls are key factors that determine the precision and quality of the final product. We offer a variety of rolling mill models to suit your needs, including our classic 2-Hi and 4-Hi rolling mills. For specialized applications, you may require a mill with a multi-roll configuration or custom rolls to achieve specific thicknesses and surface finishes.

4. Automation and Control Systems: Modern rolling mills often feature advanced automation and control systems that allow for precise adjustments and monitoring during operation. Choose a model with the level of automation that suits your operational needs, balancing cost and technological sophistication.

5. Maintenance and Durability: Consider the ease of maintenance and the durability of the rolling mill. A reliable, long-lasting model can minimize unplanned downtime and reduce overall operational costs. Be sure to choose a rolling mill with a proven track record of performance and longevity.

6. Energy Efficiency: In today’s industrial environment, energy efficiency is a key factor in minimizing operational costs. Some rolling mills are designed with energy-saving technologies that can reduce power consumption and lower costs over time.

7. Customization and Scalability: Depending on your future growth plans, it may be advantageous to select a rolling mill model that offers flexibility and scalability. This will allow you to easily adjust the setup as production requirements change and expand.

8. One-Stop Solution: We not only manufacture a wide range of precision rolling mills but also assist in planning your entire factory. From the layout of water and electrical systems to the supply of supporting equipment, we manage every aspect of the process.

Complete Solutions for Precision Cold Rolling Mills

At Sky Bluer Industries, we provide comprehensive solutions for precision cold rolling mills, tailored to meet the diverse needs of various industries. Our precision rolling mills are engineered for high precision and efficiency in processing metals such as steel, stainless steel wire, aluminum, copper, and titanium. From design and manufacturing to installation and ongoing technical support, we ensure a smooth and reliable experience for our clients. Additionally, we offer customized solutions, including advanced automation systems and maintenance services, to help optimize productivity, minimize downtime, and enhance the quality of your final products. Trust us for all your cold rolling mill needs.

Playlist

0:16

0:16

0:16