All You Need To Know About Carbon Steel Wire Production Line

All You Need To Know About Carbon Steel Wire Production Line

Understanding the Carbon Steel Wire Production Line and Its Industrial Applications

The carbon steel wire production line is specialized equipment designed for manufacturing carbon steel wire, a high-strength material composed of steel with varying carbon content. Wire with low carbon content is referred to as low carbon steel wire, while wire with high carbon content is classified as high carbon steel wire. Known for its durability and cost-effectiveness, carbon steel wire plays a crucial role in a variety of industries.

In the construction sector, carbon steel wire is primarily used to reinforce concrete structures, such as in rebar and wire mesh. Due to its strength and resilience, it is essential in the automotive industry for producing components like springs, cables, and suspension parts. In manufacturing, carbon steel wire is vital for making fasteners, wire ropes, and mesh materials. Its versatility, ease of shaping, and ability to withstand heavy loads make carbon steel wire indispensable for a wide range of applications, from everyday consumer products to critical industrial equipment.

Expert Solutions for Carbon Steel Wire Production Equipment

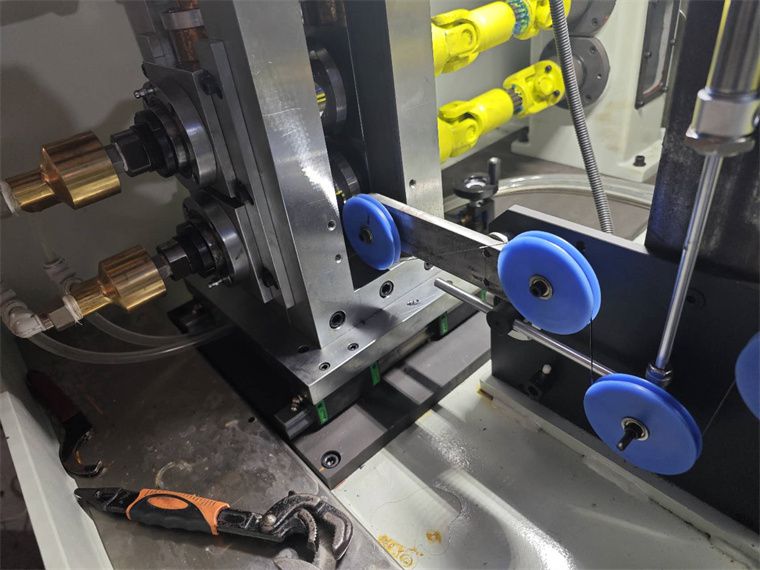

Our factory, located in China, is a leading manufacturer specializing in the production of carbon steel wire production lines. We offer a range of advanced equipment, including high-precision carbon steel wire drawing machines and precision rolling mills. Based on your specific needs and the size of the finished product, we provide customized solutions, with a focus on fine wire drawing machines and straight-line wire drawing machines, which are available in standard models. In addition, we also produce non-standard equipment, such wire flattening rolling mill machine, which can be used to create various wire shapes, including flat, rectangular, and water-drop shapes, triangular wire, among others.

What is Carbon Steel Wire Manufacturing Process?

The carbon steel wire manufacturing process consists of several key stages that transform raw steel into high-strength wire. While the process for producing thin wire differs from that for bigger wire, and the method for round wire differs from flat wire and shaped wires, some steps remain consistent across all types. First, steel is melted in a furnace, where it is mixed with scrap metal and other raw materials. The molten steel is then cast into billets or bars. During the hot rolling stage, these billets or bars are heated and passed through rollers to reduce their diameter and form the wire. The wire is then cold drawn, pulled through a series of dies or rollers to achieve the desired thickness and tensile strength. In some cases, the wire is annealed by heating and slowly cooling it to enhance ductility. Finally, the wire may be coated or treated to improve corrosion resistance before being cut to the required size. This process produces carbon steel wire that is durable, flexible, and suitable for a wide range of industrial applications.

What Is What Is High Carbon Steel Wire Used For?

High carbon steel wire is primarily used in applications that require exceptional strength, durability, and resistance to wear. Thanks to its high carbon content, it is significantly stronger and harder than other types of steel wire, making it ideal for producing components that must withstand heavy stress. Common applications include automotive parts such as springs, brake cables, and suspension systems, as well as construction, where it is used to reinforce concrete with rebar and wire mesh. Additionally, high carbon steel wire is crucial in machinery for manufacturing wire ropes, cables, and tools like cutting blades, as it can endure fatigue and abrasion. Its superior strength also makes it essential for industrial uses, including springs, fences, and various mechanical parts that must perform reliably in demanding environments.

High Precision Wire Drawing And Rolling Systems

Sky Bluer Industries China is a leading Chinese enterprise with extensive expertise and experience in supporting businesses with carbon steel wire drawing machines. We offer a comprehensive, one-stop solution, backed by world-class technology and a rigorous quality control system, ensuring the highest standards in wire production.

On-Time Delivery Service

You Can Trust You can trust us to deliver your carbon wire drawing machine and rolling system on time. We understand that delays can lead to significant challenges on the job site, which is why we prioritize punctual delivery. Regardless of your location or project requirements, we ensure that you receive exactly what you need, when you need it. Choose us for reliable, on-time delivery, every time.

Industrial Filed We Serve

We can customize any type of wire drawing machine to meet the specific requirements of your project. Let Sky Bluer Industries China assist you in designing and manufacturing high-quality carbon steel wire tailored to your needs.