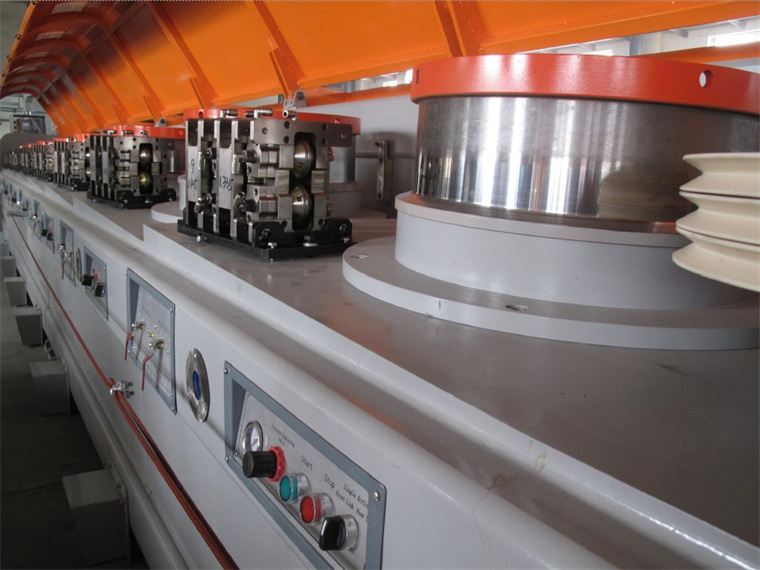

Super Fine Wire Drawing Machine

CRM2024-31 Super Fine Wire Drawing Machine, also known as Extremely Fine Metal Wire Drawing Machine, draws copper wire, stainless steel wire, and carbon steel wire from 0.03-0.08mm to 0.05-0.10mm in diameter.

With CRM fine-wire drawing machines, you are able to achieve the highest levels of precision for superfine wire production. As a result of their highly economic design, they are very popular among customers. In addition to being easy to operate, they have perfectly thought-out ergonomic features.

Types of Super Fine Wire Drawing Machine

- Type1-Super Fine Copper Wire Drawing Machine

- Type2-Super Fine Stainless Steel Wire Drawing Machine

It's used for drawing copper wire from 0.03-0.08mm to 0.02-0.04mm

Model | CRM2024-31 |

Die (no.) | 31 |

Input Wire (mm) | 0.30mm-0.80mm |

Output Wire (mm) | 0.05mm-0.10mm |

Max. Speed (M/min) | 1200M/min-1800M/min |

Driven Motor Power (KW) | 11KW |

Annealing Capacity (KVA) | 100KVA |

Method for Take-up | Bobbin |

It's used for drawing 0.03-0.12mm Stainless Steel Super Fine Wire.

Model | 24VB |

Inlet diameter | 0.45-0.7mm |

Outlet diameter | 0.03-0.12mm |

Quantity of drawing dies | 24 |

Slip ratio of main machine | 9% |

Slip ratio of last die | 6% |

Max. Drawing speed | 1200m/min |

Using motor/ main motor | 5.5kw |

Usage | Bare stainless steel wire drawing |

Correction system | Automatically control |

Annealing method | DC three section annealing |

Voltage | 380V or Customized |

Brake | Pneumatic brake |

Color | As customer's need |

Brand | CRM |

Operation direction | Right hand machine |

About us

Founded in 2016, sky bluer industries is one of the most important manufacturers of modern wire drawing plants as well as ultra-fine wire processors. The mission of our company is to design cutting-edge drawing machines tailored to the unique production requirements of each customer. As 80% of our machines are exported to European countries, we provide fast, durable, and user-friendly wire machinery to global customers, including straight line wire drawing machines, wet wire drawing machines, inverted vertical drawing machines, and ultra-fine wire drawing machines. For every industry and application, we’re here for you.

Features

- Customizable to bobbins of various sizes

- Other functions can be added(Measurement of final wire diameter, automatic bobbin replacement, etc.)

- Automatic tension control by dual-inverter.

- Zero-slip pilot design,

- High productivity

- High quality finished wire.

- High Speed

- Drive and control by AC three phase dual-inverter

Why Is Annealing Necessary for Super Fine Copper Wire Drawing Machines?

Due to the strong stretching required by the drawing process, metal materials continue to accumulate strain energy and residual internal stress, making them relatively fragile, which will lead to a lot of hidden dangers during processing and use later. A general requirement for annealing copper wire materials that have been drawn is to overcome the above problems. With the help of annealing, metal materials can be transformed in terms of their organizational structure and lattice morphology, defects such as grain boundaries and crystal planes can be eliminated, and strain energy and residual internal stress can be reduced by heating them at a specific temperature and cooling them appropriately.

Therefore, the copper wire rod material can be distributed more evenly and stably throughout the material, has greater ductility and plasticity when processed and used, and is extremely stable. Additionally, annealing can improve metals’ hardness, strength, latent yield, forging ability, and hot workability.

Video Collection

Discover Our Video Collection

If you’re looking for super fine wire drawing machines, check out the video below to find out what we produce and how they work. We’d be glad to answer your questions about our equipment at any time.

Video Series