Copper Wire Rolling Machine

This is a common question among manufacturers working with copper wire and brass wire. Many users are unsure when to choose a rolling mill over a wire drawing machine, especially when producing wires of specific sizes and surface requirements.

In this blog, we’ll explain the key functions and advantages of a copper wire cold rolling machine, helping you understand when and why it’s the right choice for your production line. Whether you’re dealing with flat, shaped, or ultra-fine wire, this guide will provide valuable insights into selecting the right equipment for your needs.

Understanding the Copper Wire Rolling Machine

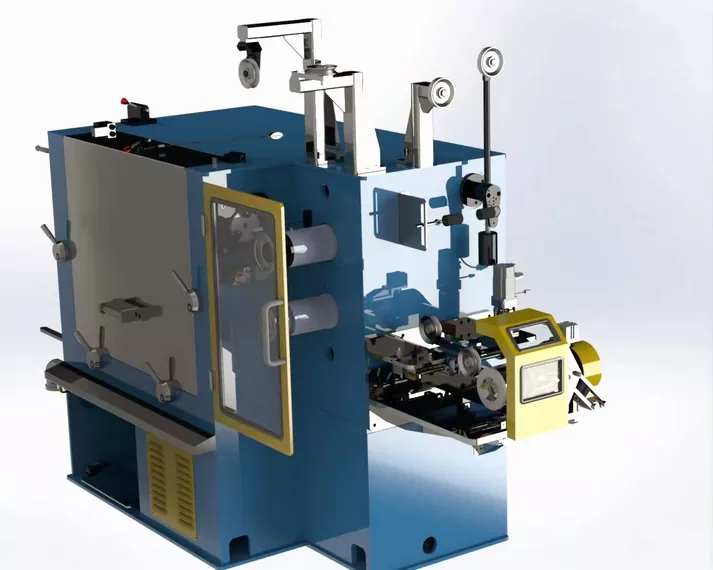

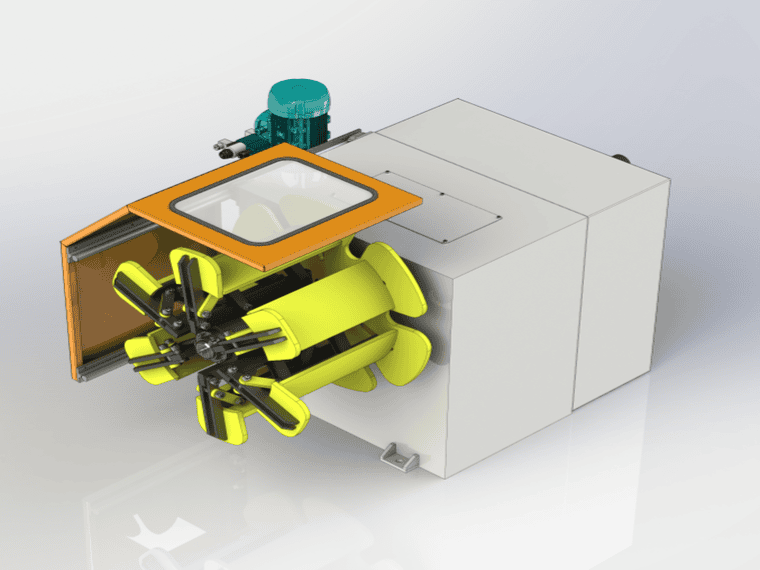

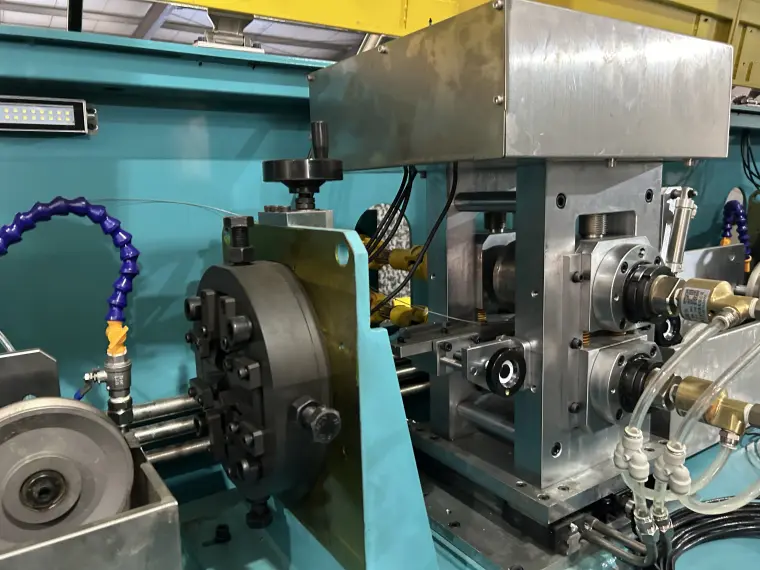

The copper wire rolling machine developed by Sky Bluer is a high-precision solution designed to reduce the diameter of copper wire while enhancing its surface finish and mechanical properties. Unlike conventional drawing machines that pull wire through dies, Sky Bluer’s rolling machine uses a fully die-free rolling process—relying solely on precision rollers to shape the wire.

This advanced technology offers several key advantages:

- Exceptional surface quality, free from scratches, burrs, peeling, or other defects

- No need for die maintenance, eliminating the cost of die inventory and mold grinding personnel

- Lower operating costs and improved production efficiency

Sky Bluer’s rolling machines are particularly suited for producing flat, shaped, or ultra-fine copper wires, which are widely used in solar PV panels, electronics, connectors, and telecommunications cables. With its innovative design and outstanding performance, Sky Bluer is helping manufacturers worldwide meet the growing demand for high-quality copper wire products.

Which types of copper wire are best suited for rolling mills, and which are better produced using wire drawing machines?

Copper wire types suitable for rolling mills vs. wire drawing machines

Rolling mills are best suited for producing flat, square, water-drop, shaped, and precision copper wires, such as:

- Flat wire (used in photovoltaic ribbons, busbar ribbon connectors, Military cables, special cables and transformers)

- Rectangular or square wire (Magnet wire, enameled wire)

- Shaped wire (e.g., D-shape, trapezoid, or custom profiles)

- Ultra-fine wire with tight surface quality requirements

Rolling mills provide excellent surface finish, dimensional accuracy, and are ideal when the wire must have no surface defects, such as burrs, scratches, or peeling.

On the other hand, wire drawing machines are more suitable for producing:

- Round copper wires (Magnet wire, enameled wire, Silver-plated copper wire, cable)

- Large diameter reductions through multi-pass drawing (Rod Break Down machine)

- High-speed production of standard conductor wire (CTC line, wet drawing machines,22D wire drawing machines, Phosphor bronze wire drawing machine)

Wire drawing is ideal for applications where high tensile strength is needed and surface quality is not as critical.

In summary, use rolling mills when shape and surface quality are your priority, and choose wire drawing machines when you’re focused on reducing diameter for round wire at high speeds.

Why Do Users Prefer the Copper Wire Rolling Mills Manufactured by Our Company?

Our copper wire rolling mills are globally recognized for their precise performance and exceptional surface finish, thanks to a range of advanced features designed to optimize every aspect of production:

- Automatic pay-off system ensures smooth, uninterrupted wire feeding for enhanced efficiency

- Motor-controlled pressing system paired with a parallel adjustment device provides precise control over the rolling radius for consistent shaping

- Motor-driven side mill (model ElSS) with a fast bed change system, allowing quick and easy roller replacement to minimize downtime

- Dancer system strategically placed between stations facilitates easy machine setup and maintains consistent wire tension throughout the process

- High-efficiency filter system for spray coolant delivers optimal lubrication and cooling during rolling, protecting both the wire and equipment

- Continuous automatic measurement and control of wire dimensions, guaranteeing strict adherence to size tolerances

- Adjustable speed settings accommodate a wide range of production requirements and wire specifications

- Rapid roller change capability further enhances operational flexibility and reduces maintenance time

Together, these integrated technologies ensure our rolling mills produce reliable, top-quality copper wire that meets the highest industry standards and customer expectations

About the Company

Sky Bluer Industries, based in China, specializes in the manufacturing of wire flattening and shaping machines, precision cold wire rolling machines, annealing equipment, and wire drawing machines. By integrating advanced rolling processing technology imported from Japan, we deliver exceptional precision—achieving a roundness tolerance of less than 0.001mm and a superior surface finish as fine as 0.02μm.

Committed to excellence, Sky Bluer provides comprehensive, one-stop turnkey solutions tailored to meet the diverse needs of industries worldwide. Our focus on quality, innovation, and customer satisfaction positions us as a trusted partner in metal wire processing equipment.